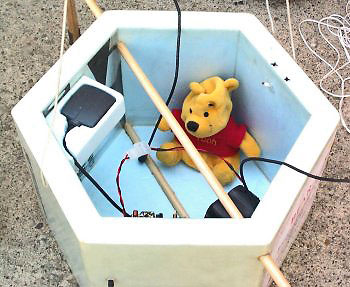

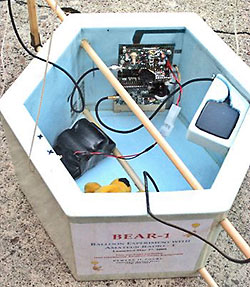

BEAR 1 & 2 Flight Capsule Construction

|

SM foam board was cut on a table saw for the flight capsule. |

|

|

Pieces were held together with masking tape while being dry fitted and then glued with epoxy resin. | |

|

Extremely light (0.6 ounce) fiberglass cloth was applied after lightly sanding the foam pieces. The cloth is cut to size and positioned on box. |

|

|

Epoxy resin, thinned with 99% isopropyl alcohol to cream consistency is applied, starting at the center and working towards the edges. Thinning the resin makes it easier to apply and also reduces the amount which is applied and therefore the weight of the finished capsule as well. |

|

|

A close-up of one of the corners showing how nicely the light cloth flows around a corner with out any creases. | |

To provide strain relief for the supporting cords, 3 pieces of nylon rod were cut and drilled out to accept the supporting cords diameter. External threads were then cut to help the epoxy adhere that was used to glue them into the holes drilled

in the side panels of the foam box. To provide strain relief for the supporting cords, 3 pieces of nylon rod were cut and drilled out to accept the supporting cords diameter. External threads were then cut to help the epoxy adhere that was used to glue them into the holes drilled

in the side panels of the foam box. |

||

|

Here glass cloth is being applied to the exterior of the box. Box is 12" in diameter, 8" high and constructed of 1" thick foam board. Completed box weight was 219 grams (7.7 oz). The covering adds strength, protects the foam from impact damage and the additional 15% weight is well worth it if the box is going to be used again. (the extra weight is actually <5% when the other capsule components, like the antennas and parachute, are considered. |

|

|

|

||||||||||||

| To BEAR Home Page |