2 Ring HAB ReleaseWe wanted something simple, easy to build, light weight and reliable that we could install at the parachute apex and use to release the line from the balloon we attach there. We tried a number of the commonly used methods and after finding problems with each we came up with the following 2 ring release that's based on the 3 ring release system used by skydivers. Keep in mind that the release shown in the photo's is a prototype which was built in about hour at the last minute and that there are better ways to do some things, like how to attach the servo motor rather than simply gluing it in place permanently for example, but the release is reliable and works every time just the same.

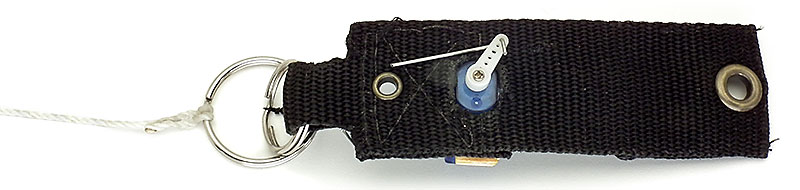

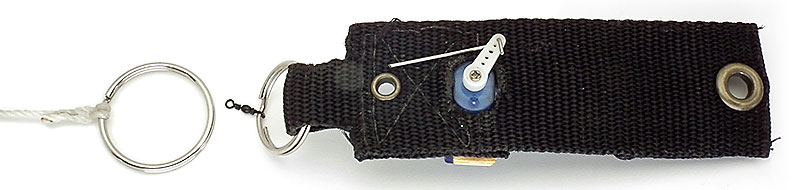

The webbing is from one end of an extra camera bag strap with attachment rings that was was cut off (the other end can be used for a second release of course). The cut end of the piece cut off was then folded over, stitched together and a metal grommet was installed for the short line that will later attach the strap to the parachute apex where the line from the balloon is usually attached. The ring was then passed through one eye of a fishing line swivel and a second smaller metal grommet was installed at the other end of the strap for the fishing line swivel to pass through. A small R/C servo was then glued to the strap with it's shaft through the strap and the release was basically finished.

The line from the balloon now attaches to a metal ring slightly larger than the one on the strap and to connect the balloon to the parachute the smaller ring on the strap is passed through larger ring and then flipped back over the larger ring with the fishing line swivel placed through the smaller metal grommet.

Flipping the assembly over shows how a small metal pin attached to the servo arm is then passed through the other fishing line swivel eye which now keeps the larger ring trapped until the servo motor is activated.

Activating the servo motor pulls the pin from the eye of the fishing line swivel . . .

. . . which releases the trapped larger ring. The required pin removal force is very small regardless of the weight being released, unlike similar methods where a pin is pulled from a hole in a plate that the balloon line is attached to and the required force to pull the pin quickly increases with increased weight due to increased friction and the pin too hard to remove without an overly large heavy motor and mechanism. A 5V servo motor was used and we use 4-5V during flights, but during testing we only used 2V and had no problem releasing loads up to100 lb. (Any heavier and the nylon cord we used would have likely broken) Any regular R/C servo motor can be used and we used a tiny 5 gram $3 one from China, but since we aren't using it as a servo with an R/C transmitter & receiver and simply want a small geared down motor to turn a servo arm when voltage is applied it had to be modified slightly. To make an R/C servo operate by simply applying 3-5V is the easy part and just requires opening up the servo, removing the electronics which requires removing the 3 wires connected to the feedback potentiometer, the 2 wires connected to the motor and connecting the 2 wires you will be using to power the motor with directly to the motor. The next part is a bit harder, depending on how small of servo is used. The feedback potentiometer can't simply be removed as it's shaft is used for the gear train output shaft, however we want continuous output rotation and the potentiometer has built in stops that prevent this so the stops must be removed. I'm not going to give details of how to do this, other than to say that the small size of things doesn't make it real easy and one of the more tiny moto-tool grinding bits is what I've found best to grind down the tiny stops with. We power our release from the same 5V regulator supplying power to the micro controlling the release using 2 small twisted 28 AWG conductors which are run along one of the parachute lines from the payload box to the release. With no protection from the cold, we were concerned about motor problems, but the actual motor didn't show any signs of being affected by the −18°C temperature inside a freezer and any trace of the grease used to lubricate the gear train was removed to prevent it being a problem. Some feel a heated nichrome wire to melt through and cut the nylon line from the balloon would have been easier, but this takes a lot of power which requires conductors too large to run up the parachute lines or a battery too too large and heavy to allow placing it on top of the balloon. A hot wire cut down device also takes a lot of time to make reliable plus there's the problem of not being able to solder to nichrome wire. |

|

| To BEAR Home Page |